Look up the Z value of 1.365 in a Normal Distribution table to get the probability of the project taking 42 days.

Compute the Z value: Z (absolute time difference) / Std.

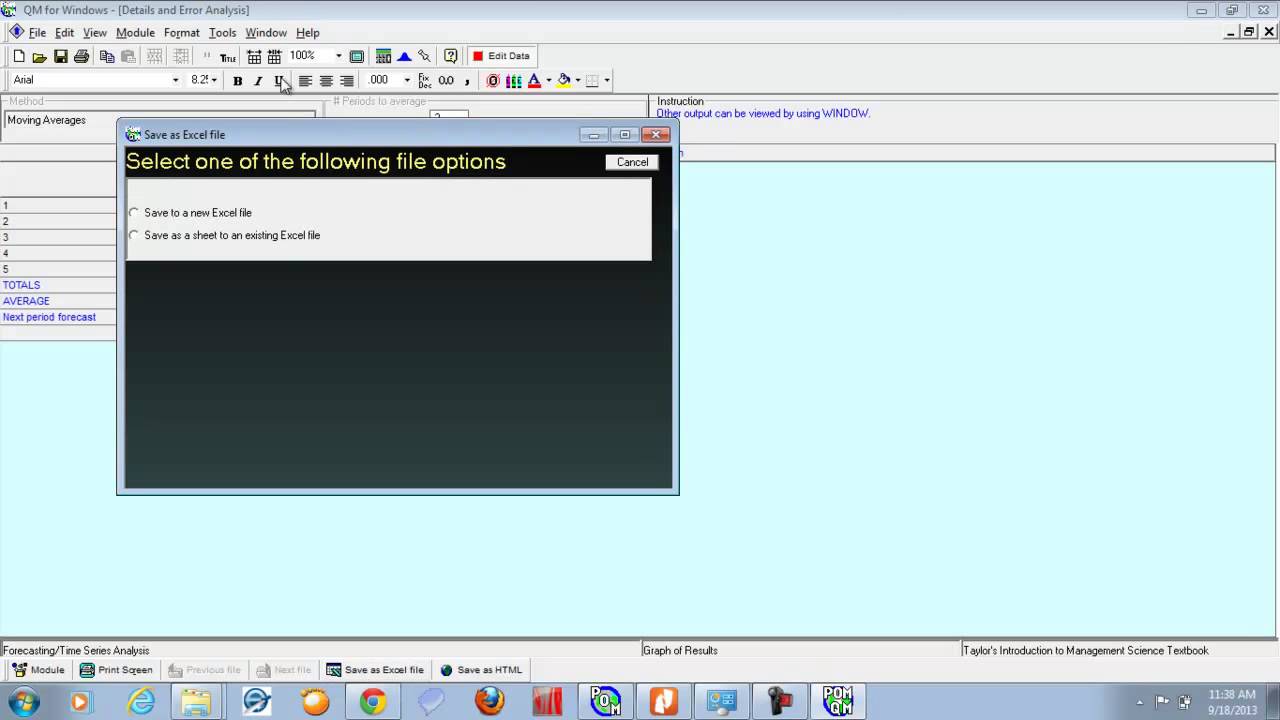

Pom qm dual value meaning software#

1.465 POM/QM software gives you the variance of the critical path.

Pom qm dual value meaning windows#

Furthermore, enhanced nucleating ability and crystallization kinetics of the PLA matrix were revealed as specific characteristics. linear programming using the POM-QM for Windows 5. The square root of the variance of 2.147 Std. High performance optimized for mobile, quad core. High performance optimized for mobile, unlocked. As a result, good thermal stability associated to high tensile strength, and noticeable increases in impact properties were recorded. Graphics level (processors with new integrated graphics technology only) E. Enter Shipments for the Changing Variable Cells. You have the choice of typing the range names or clicking on the cells in the spreadsheet. The surface silanization treatment proved to improve the quality of the nanofiller dispersion even at higher loading. The result should be consistent with the picture below. value, but also to raise some questions regarding its meaning and. However, with few exceptions, TGA and DSC measurements did not reveal important changes of thermal parameters. The measurement aspects of quantum mechanics (QM) are as old as QM itself. As demonstrated under dynamic solicitation (DMA), melt-blending PLA with HNT led to enhancement of storage modulus (E′) and offers the possibility to use PLA in applications requiring higher temperatures of utilization. National in month 3, we add the two branch probabilities in Figure F-1. The nanocomposites were characterized by higher rigidity (with Young’s modulus increasing with HNT loading), higher tensile strength (about 70 MPa at 6 % HNT(QM)), whereas the elongation at break and impact strength did not decrease. Now that we have defined a Markov process and determined that our example. The morphology, thermal, tensile and impact strength properties of the nanocomposites containing 3–12 % HNT were evaluated and compared to those of pristine (unfilled) PLA.

HNT were also surface treated by silanization reaction with 3-(Trimethoxysilyl) propyl methacrylate (TMSPM). To evaluate the potential of halloysite nanotubes (HNT) as nanofiller for polylactide (PLA), various nanocomposites have been successfully produced by melt-blending the polyester matrix with HNT (HNT(QM)). Murariu, Marius Dechief, Anne-Laure Paint, Yoann Peeterbroeck, Sophie Bonnaud, Leila Dubois, Philippe Polylactide (PLA)-Halloysite Nanocomposites: Production, Morphology and Key-Properties Polylactide (PLA)-Halloysite Nanocomposites: Production, Morphology and Key-Properties

0 kommentar(er)

0 kommentar(er)